- Home

Safety Signs

BOC provides a range of caution, hazchem & prohibition signs to warn, instruct & inform workers about workplace safety compliance. Each workplace is responsible for their own compliance to relevant Australian Standards, work, health & safety legislation

-

Filter

- 14 Results

-

-

- Select More than 1 Item

- Compare (up to 4 products)

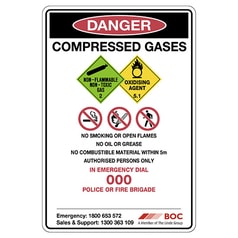

All in One Compressed Gases Storage Safety Sign

285 x 420mm All in one safety sign for compressed gas storage areas. Available in weather resistant polypropylene and durable metal.

-

From $39.00 each

excl. GST

All in One Compressed Oxygen Storage Safety Sign

200 x 280mm All in one safety sign for compressed oxygen storage areas. Available in weather resistant polypropylene and self adhesive material.

-

From $27.92 each

excl. GST

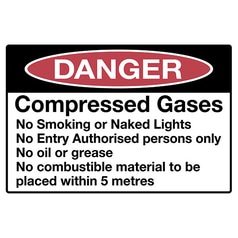

Danger Compressed Gases Sign

Danger Compressed Gases Sign.

-

$49.35 each

excl. GST

Oxygen in use door hanger pack of 2

Oxygen in use door hanger pack of 2

-

$5.00 each

excl. GST

Full Cylinder Polyurethane Hanger Sign

Durable and weather-resistant hanger sign to identify full cylinders

-

$6.50 each

excl. GST

Empty Cylinder Polyurethane Hanger Sign

Durable and weather-resistant hanger sign to identify empty cylinders

-

$6.50 each

excl. GST

Flammable Gas 2 Hazchem Sign

270 x 270mm red Flammable Gas 2 Hazchem metal sign

-

$26.73 each

excl. GST

Dangerous Goods Hazchem Metal Sign

Black & orange striped Dangerous Goods Hazchem 270mm x 270mm metal sign.

-

From $32.27 each

excl. GST

Flammable Liquid 3 Hazchem Sign

Flammable Liquid 3 Hazchem sign - 270x270mm

-

From $25.38 each

excl. GST

Full Cylinders Sign

Full Cylinders sign, available in metal

-

$39.00 each

excl. GST

Empty Cylinders Sign

Empty Cylinders sign, available in metal

-

$39.00 each

excl. GST

-

Filter

Filter - 99 Results

-

-

[ Aluminium Melting BOC Australia - A Linde company Industries Aquaculture Agriculture Chemicals Construction & Infrastructure Electronics Food, Beverage & Leisure Food processing Glass Processing Healthcare Metal Fabrication Metal Production Direct Oxygen Injection Oxygen Enhanced Combustion Inerting for Metal Production Heat treatment for Metal Production Additive Manufacturing Aluminium Die Cooling Aluminium Melting Aluminium Dross Cooling Sub-zero Parts Freezing Mining Steel & Metals Oil and Gas Pharma & Biotechnology Plastics & Rubber Power & Energy Retail Refining Space Mobility & Transport Water & Wastewater Treatment Aluminium Melting BOC has developed and commercialised several proprietary oxygen-injection techniques, oxy-fuel combustion systems, and aluminum melting burners that enhance the productivity and efficiency of aluminum melting furnaces. Oxygen injection increases the heat available in the furnace for melting by reducing the heat loss due to hot nitrogen in the flue gas. Oxy-fuel combustion for secondary aluminum melting provides many benefits compared to conventional air/fuel combustion. These benefits include: Increased flame temperature Increased productivity Reduction in flue gas Fuel savings The reduction in the flue gas volume and particulate material entrainment with oxy-fuel combustion greatly reduces the cost and complexity of off-gas cleaning systems. Want to find out more? If you would like to find out more about BOC's metal production solutions, please complete our contact form and we will be in touch. Contact us ]

-

[ BOC Gas: In-store Pick Up ]

-

[ BOC and SPW Partnership Exciting News! South Pacific Welding Group (SPW) and its locally managed stores, are proud to partner with BOC to become the go-to destination for all your welding supplies and quality BOC gases. We’re joining forces to now offer customers an even bigger range of global brands, local service and trusted advice through our growing network of 90 stores across Australia and New Zealand. Over time, these stores will change with a new look… and some with a new location. Our people will continue to be your local gas and welding specialists with the know-how to help you get the job done. BOC will continue to serve all your gas needs. Keep an eye out for exciting changes coming to a store near you - Click Here To See Your Local Store Location ]

-

[ Welding & Cutting Hazards Health & Safety Cylinder Information Acetylene Cylinder Safety Safety with Liquid Nitrogen LPG Cylinder Safety Safety Training Sensitive Chemicals Declaration Welding & Cutting Hazards Cylinder Safety MMA Welding TIG Welding MIG Welding Heat Stress Confined Space Electrical Safety Noise Magnetic Fields Burns Light and Heat Radiation Ozone Eyes Metal Fume Fever Measurement of Fume Material Process Fume Particulate Fume Gaseous Fume Chromium in Fume Incident Response Welding & Cutting Hazards Welding and Cutting operations present a variety of hazards, not only to those carrying out the operation but in many instances to others in the vicinity. In the workshop there are a number of hazards specific to welding or cutting and others, of a more general nature, which may also be present in the fabrication environment. Did You Know? There are many different types of potential hazards in welding and thermal cutting processes. Everyone involved should be aware of what these hazards are. Welding and cutting processes are safe, and the risks from the hazards can be reduced, if they are carried out correctly and with care. Potential hazards need to be identified, measured where appropriate, and assessed, and remedial measures put in place wherever necessary. Although Personal Protective Equipment, PPE, should not be issued as the primary method of reducing a hazard it should be issued to all personnel if beneficial. Employers and employees should be made fully aware of the dangers that can arise and take all reasonable care to ensure the health and safety of all. Types of Hazards The hazards encountered in welding and cutting may be sub-divided into groups as follows: Electrical Magnetic Fields Compressed Gases Fuel Gases Inert Gases Cryogenic Gases Radiation Heat, Flames, Fire and Explosion Welding Fume and Gases Noise Material and Manual Handling Confined Spaces Thoriated Electodes Solvents Downloads Electrical safety single phase equipment A3 poster(PDF 2.0 MB) ]

-

[ BOC raises the bar with new F3VIPR cylinder range delivering ultimate convenience and portability for welding industry News & Media Press Releases Case Studies Media Contact Competitions AU BOC @ Social Media BOC raises the bar with new F3VIPR cylinder range delivering ultimate convenience and portability for welding industry Press Releases Leading gases and engineering company BOC today announced its latest innovation for the welding industry with the launch of the new F3VIPR, 33 litre high pressure cylinder with in-built variable integrated pressure regulator (VIPR). Kyle Scott, Business Manager Specialised Manufacturing, said BOC’s technical experts are committed to raising the bar in cylinder technology and are proud to be delivering unique design features that provide enhanced convenience and safety for its customers. “The F3VIPR range provides busy welders and manufacturers with an all-in-one cylinder solution that improves productivity by eliminating hassles associated with acquiring, fitting and maintaining a separate regulator. Usage can also be tracked with a content indicator showing the amount of gas left. “With safety as our number one priority, we have enhanced portability by making the F3VIPR shorter than a G or G2 cylinder, with a handle to assist with trundling, allowing for better manoeuvrability around workshops and sites. “The 300 bar high pressure has also allowed us to increase gas content in most F3VIPR shielding gas traffics compared to existing G size cylinders with up to 13 percent content increase on our 065G ARGOSHIELD® Universal.” BOC has invested significantly in upgrading its cylinder fleet with more than 550,000 new cylinders introduced over the past five years and has a $15 million world leading cylinder testing facility at its Sydney Operations Centre. The F3VIPR is now available in 18 of BOC’s ARGOSHIELD®, STAINSHIELD®, ALUSHIELD® and Argon gas mixtures and is compatible with a Standard 5/8” fitting, which means it will work with existing hoses and connections. Available now at BOC Gas & Gears across Australia or online at www.boc.com.au . Further enquiries: Further enquiries: Suzanne Gibbs Head of Communications, RSP Email: suzanne.gibbs@boc.com Email ]

-

[ Careers It starts now At Linde, every day is an opportunity: an opportunity to learn, to grow, to share success and to contribute to one of the world’s leading industrial gas and engineering companies. Seize the opportunity: take your next step with us. Find a job at your favourite location Search for the right job The Trainee Programme @ Linde Engineering Are you keen to keep learning and developing a global mindset? Then the Linde Engineering Trainee Programm with its three different tracks is meant for you. Interested? Find out more. What sets us apart? See what it means to work at Linde: your chance to really get to know us. What opportunities lie ahead? Discover our diverse range of jobs: each one as important as the next. Before you apply… Get to know how we select candidates, get insider tips and advice and more… Insider Story: Giving back Kasia has successfully made her way up the ranks during her time at Linde. Did you know? If we were to combine all our installed hydrogen vehicle or fuel-cell vehicle fueling capacity, we could travel 1.4 bn km emission free – from earth to Saturn (and even a little extra turn). Latest Updates By clicking on a post, you are aware and you agree that your personal data (in particular your IP address) may be transferred to the respective social media provider and be processed and used by him as described in further detail in his privacy policy. You can find more information on the social media providers and the personal data being transferred in our Privacy Policy under the section dealing with the Social Media Wall. Find us on Find us on Find a job at your favourite location Search for the right job ]

-

[ BOC Gas: Looking for a Document Looking for a Document Find and print an invoice It’s easy to find an invoice anytime, anywhere using My Account. Register or Sign In to My Account Select Invoices The last 6 months worth of unpaid invoices will be displayed and you can change the date range, status and type or find an individual invoice Click Download next to the invoice you want to download In the popup, click Click here to Download next to Invoice Can’t find what you were looking for? Please feel free to contact us using live chat , call 131 262 to speak with our friendly Customer Service team or request a copy of an Invoice . Alternatively, Register or Sign In to My Account and select Personal Profile & Account Preferences to edit Invoice Preferences and receive your invoice directly to the email of your choice. Find and print a statement You can download your statement anytime, anywhere using My Account. Register or Sign In to My Account Select Account Balance & Statements You can now see your account statements for the last 12 months. Click Download next to the statement you want to get a copy of Can’t find what you were looking for? Feel free to contact us using live chat , call 131 262 to speak with our friendly Customer Service team or request a copy of a Statement. Find and print a proof of delivery It’s easy to find a proof of delivery docket anytime, anywhere using My Account. Register or Sign In to My Account Click Order History. The last 3 months of orders will be displayed You can search for an individual Proof of Delivery if you have an order number or alternatively search all orders within a selected date range. Click Show Documents for the order you want to find the Proof of Delivery for. In the popup, click Download next to Delivery Note We are committed to ensuring your Proof of Delivery (POD) documents are available within 24 hours of delivery. If you are unable to see the Proof of Delivery you are looking for, please contact us using live chat , call 131 262 to speak with our friendly Customer Service team or request a copy of a Proof of Delivery . Safety Data Sheets A Safety Data Sheet (or Material Safety Data Sheet) contains important information about the characteristics and actual or potential hazards of a substance. These can be an extremely useful source of information enabling you to remain vigilant on the potential hazards of our products and how best to use them safely. To obtain a Safety Data Sheet Enter a Part Number or product name in the search bar at the top of this page Click Search Click the product name or image in the list of search results Click the Downloads tab at the bottom of the product page Click the Download Safety Data Sheet link Safety Data Sheets can also be found here or are listed on the Order Confirmation page when you order online If you are unable to find what you are looking for please contact us using live chat , call 131 262 to speak with our friendly Service team or send us an enquiry via email Batch Certificates A BOC Batch Certificate or Certificate of Compliance is a formal document signed by a BOC Product Manager certifying a batch of products was rigorously tested and is suitable for sale. You can download a Batch Certificate for welding wire, electrodes and other supplies online. If you are unable to find what you are looking for please contact us using live chat , call 131 262 to speak with our friendly Service team or send us an enquiry via email . Chat Online Call Us Send Enquiry Update My Account How to Place an Order Where's My Order? Pricing & Charges Explained Returns & Refunds Chat Online Call Us Send Enquiry Update My Account How to Place an Order Where's My Order? Pricing & Charges Explained Returns & Refunds ]

-

[ BOC Gas: Welding, Cutting, Brazing & Freezing Product Selector Tool Product Selector Tool This handy tool will help you choose the right products for the job. ]

-

[ BOC Gas: Terms of Use Terms of Use This web site (boc.com.au) is operated by BOC Limited (ACN 000 029 729) for and on behalf of itself and its related bodies corporate (collectively referred to as "BOC Australia") under the domain name www.boc.com.au. Your access to this web site is subject to the terms and conditions set out in this section and elsewhere on this web site (as amended from time to time) ("Terms of Use"). Please read them carefully before proceeding as your access to and/or use of this web site constitutes your agreement to the Terms of Use. BOC Australia is part of the Linde Group. Other Linde Group web sites may contain terms of use which are different from these Terms of Use. When accessing and/or using these other Linde Group web sites please check the terms of use of each such web site as these Terms of Use may differ significantly from other Linde Group web sites. BOC Australia reserves its right to amend the Terms of Use from time to time. Any amendments become effective when published on this web site. You should review the Terms of Use regularly for any such amendments. Intellectual Property rights, Trade marks, Copyright and Rights of Use The entire content of this web site, such as text, pictures, graphics, sound, animations and videos, including corporate logos and brands, as well as the layout of BOC Australia web pages, is protected by trademark and copyright law and other laws for the protection of intellectual property and legal rights (including third-party rights). Distributing, changing or copying the contents of these pages, including framing or the use of any framing techniques, is prohibited unless the written consent of Linde AG and/or BOC Australia is obtained or such action is permitted pursuant to the limited licence detailed below. Linde AG and/or BOC Australia expressly specify that some of the pictures contained on this web site are protected by the copyright of third parties. Unless set out below, no rights of licence or other rights are granted via this web site for the use of the intellectual property contained therein, including brands and copyright. Copying, distributing, reproducing, forwarding and otherwise using this protected intellectual property is not permitted without the written consent of Linde AG and/or BOC Australia. The remaining contents of this web site may also not be copied, distributed, changed or made available to third parties. The use of texts, sections of text or visual material, in particular, requires the prior approval of Linde AG and/or BOC Australia. Linde AG and/or BOC Australia grants you a limited non exclusive licence to view the material in this web site, access material contained in this web site and use this web site according to the Terms of Use and this limited non exclusive licence. The licence is terminable at will and without notice in the event that you breach any of the Terms of Use. Pursuant to this licence the user is expressly permitted to produce a single copy of this web site for personal, non-commercial use, on the condition that the content is not altered in the course of copying and all references to industrial property rights are retained in the copy, or inserted if only extracts from this web site are used. The content of press releases and other documents classified as public may be used in public communications. This does not apply to those parts of public documents which are protected by trademark or copyright law, or other legal regulations. Legal Use It is an essential term of these Terms of Use that your use of this web site is lawful, does not infringe any third party right’s and does not breach any standards or codes of conduct published or promoted by any statutory, governmental or other relevant authority. In particular, you must not compromise or attempt to compromise the security of this web site or post, send or transmit to or through this web site any harmful, immoral, offensive or otherwise objectionable material. Disclaimer and Limitation of Liability The information contained in this web site is general in nature and is provided for your convenience. Your use of this web site is at your own risk. It is your responsibility to assess and verify the accuracy, completeness and reliability of the information on this web site using common sense, prudence and reasoned judgment, and to seek professional advice where necessary. To the maximum extent permitted by law, none of BOC Australia nor any of their respective officers, employees, shareholders, agents, or contractors makes any express or implied representation or warranty about, or shall be liable, in contract, tort (including negligence) or otherwise, for any direct, indirect, punitive, special or consequential loss, damages or reliance in connection with, this web site, its use, its content or any products or services referred to on this web site. This includes (but is not restricted to) loss or damage you might suffer as a result of any of the following: your reliance on the completeness, accuracy, suitability or currency of this web site or its content; changes from time to time in the material in this web site or delays, errors or omissions when making such changes; the use of this web site and any other site linked to this web site, including the transmission of any computer virus or the defamatory, offensive or unlawful conduct of third parties; or use of all other web pages accessed by hyperlink from the BOC Australia and/or Linde AG web site, whether these belong to affiliated companies or third parties. BOC Australia and/or Linde AG accept no liability for such web pages and are not responsible for the data protection arrangements of the operators of these web pages. The limitation on liability applies also to damages for loss of profit, business interruption or the loss of data or information. Where BOC Australia cannot exclude liability, to the maximum extent permitted by law, our liability will be limited to resupply of the relevant service, goods or equivalent goods, the cost of resupplying the service, goods or equivalent goods or, in the case of goods, the cost of repairing the goods, at our option. Any statements made on BOC Australia’s web site regarding the future of the Company, are based on the beliefs and judgement of the management of BOC Australia and are therefore subject to risks and uncertainties. BOC Australia is under no obligation to update such statements regarding the future of the Company and accepts no liability whatsoever for these statements. BOC Australia may deny access to this web site at any time and provides no guarantee of the uninterrupted availability of its web site. The failure or neglect by Linde AG and/or BOC Australia to enforce at any time any of the Terms of Use shall not be construed or deemed to be a waiver of the rights of Linde AG and/or BOC Australia under these Terms of Use. Indemnity To the maximum extent permitted by Law, you agree to indemnify Linde AG and/or BOC Australia and their respective officers, employees, shareholders, agents, and contractors and any other persons involved in the creation of this web site for all damages, losses, penalties, fines, expenses and costs (including legal costs) which arise out of or relate to your use of this web site, any information that you provide to BOC Australia through this web site or any damage that you may cause to this web site. This indemnification includes, without limitation, liability relating to copyright infringement, defamation, invasion of privacy, trade mark infringement and breaches of any applicable Australian Competition and Consumer Law. Web sites by Third Party Providers/Links This web site contains links and references to third party web sites. These links and references do not imply any endorsement of the content of third party web sites by Linde AG and/or BOC Australia. Linde AG and/or BOC Australia are not responsible for the availability or the content of third party web sites nor do they warrant that information on any third party web sites is free from computer viruses or any defects, errors or infringements of intellectual property rights and are not liable for any damage or injury resulting from their use, regardless of purpose. Links to third party web sites are provided to users of Linde AG’s and/or BOC Australia’s web site for their convenience only. BOC Australia does not permit linking to this web site unless BOC Australia’s written consent is obtained and the full html page is loaded. If such consent is provided, any such link must not incorporate Linde AG’s and/or BOC Australia’s trade marks, brands or registered trade marks, and must not be used to disparage or detrimentally impact on the reputation of Linde AG and/or BOC Australia. General Obligations must ensure that your LoginID and password that is used to access this web site and the details of your account are kept in a safe and secure manner; must contact us if you are or become aware that there is or has been an unauthorised use of your LoginID and password or account, or any other security breach relating to your account; must promptly advise us of any changes to your information provided to us as part of the customer registration process; are responsible for any costs associated with your access to or use of this web site, including Internet access fees; are responsible and liable for any person that uses your LoginID and password to order Product(s) through this web site; agree that BOC Australia may charge you for all Products that we agree to supply to you that have been ordered using your LoginID and password through this web site; and should check the labels on the Products before consumption or use. Data Protection, User Information and Privacy To enable BOC Australia to comply with your requests for information, you may be asked to supply personal data. Any such data is supplied by you completely voluntarily and is used solely for the purpose of complying with your request for information. All data is used in accordance with applicable data protection law. Personal information provided to BOC Australia or other Linde Group companies through this web site will only be collected, stored, processed and used in accordance with our Privacy Policy .Please read this carefully before going on. By providing personal information to us you are consenting to its use in accordance with our Privacy Policy . Applicable Law The Terms of Use are governed by and construed in accordance with the laws in force in the State of New South Wales, Australia. You agree to submit to the exclusive jurisdiction of the courts of that State. ]

-

[ BOC Gas: BOC Flexigas E Plan 12 - Acetylene Gas Plan $219. No Ongoing Rent. No Cylinder Deposit. Home Plans Dissolved Acetylene E Plan Content for FullForEmpty Attribute Content for No New Business Attribute Previous Next Previous Next Dissolved Acetylene E Plan 12 The Dissolved Acetylene E Plan is ideal for low gas usage of 1-2 refills per year of E Size (3.2m3) Acetylene cylinders. One annual payment includes 1 full bottle. Rent free, no deposit and no need to BYO bottle or cylinder. More information $219.00 per year incl. GST / Price includes 1 full bottle Available: Pick Up | Delivery Sign Up To Plan Plan Details Plan Details Low Usage Ideal for 1-2 refills per year One annual payment includes 1 full bottle No Ongoing Rent No Cylinder Purchase No Deposit The pricing outlined in this offer is subject to BOC General Terms and Conditions of Supply. The prices exclude any Delivery/Handling charges which may be applicable at the time of purchase. Pre-paid plan offer is not transferable or redeemable for cash or credit. Additional Product Charges will be varied in proportion to changes in BOC's standard prices for each individual product unless otherwise stated in this agreement. This is a rolling plan charged annually unless the cylinder(s) have been returned at renewal date or you advise BOC otherwise. Any cylinders supplied over the agreed plan quantity will be charged at non-plan pricing and rental will apply. All prices include GST. Related Plans Acetylene D Plan $108 per year (1m3 of gas) incl. GST View details Acetylene G Plan $319 per year (7m3 of gas) incl. GST View details Oxygen E Plan $149 per year (4.1m3 of gas) incl. GST View details < ]

-

[ Frequently asked questions Supply and Service Supply Options Supply Channels Services Application Technology Centres ACCURA gas cylinder management Cylinder Upgrades Frequently Asked Questions EVOS VIPR F3VIPR Cylinder G3VIPR Cylinder Safety Training Frequently asked questions Here you can find answers to some commonly asked questions. Raise The Bar - Cylinder Upgrades Click on a question below to view the answer Why is BOC introducing this new cylinder? BOC is introducing new cylinders in response to customer demand. They are a lightweight steel cylinder (compared to other high pressure cylinders) manufactured to international standards, and can be filled to a higher pressure and content than our older cylinders. This means that at a constant flow rate the new high pressure cylinder lasts longer than the older cylinders. Why are these new cylinders better? These cylinders have several features that differentiate them from the older, lower pressure cylinders. Firstly, the newer cylinders can be filled to a much higher pressure. This means there will be more gas in each cylinder. As such, your new cylinder will last longer, meaning reduced downtime for you so you can keep doing what you do for longer. A large majority of these new cylinders have been fitted with side outlet complex valves. A complex valve features a non-return and minimum pressure retaining device. This device helps stop backflow and corrosion. These features assist BOC to continue to provide you with high quality industrial gases. What about the safety testing on existing cylinders? These new cylinders form part of BOC’s commitment to continuous improvement and will be introduced into other products in coming years. BOC is committed to providing a high quality and safe products to our customers. We conduct regular testing on all our products to ensure that they meet or better the specified quality. All BOC’s cylinders are visually checked each time they are filled to ensure that they are safe and in good condition. Will this new cylinder cost me more? For the new cylinders, the price of the gas per m3 will stay the same. As there is more gas in each cylinder, total price for gas in a cylinder will increase (unless there is no change in the cylinder volume, then the total price for gas in a cylinder will remain the same). Other charges including handling, delivery and container service charges will remain the same as the original cylinder. This is despite the significant investment BOC is making in these new cylinders. For example, the container service charge for a new D2 cylinder will remain the same as the schedule price of an old D sized cylinder. Please note: cylinder charges and gas pricing are subject to review. Can I opt out of getting the new cylinders? No. In order to raise the bar, BOC will be replacing the older cylinders with new cylinders. The older cylinders will be condemned and will not be available in products which have been upgraded. Is my regulator compatible with the new cylinders? Regulators manufactured to Australian Standard AS 4267-1995 can be safely used with the new high pressure cylinders. Regulators marked/stamped with AS 4267 comply. If your valve has been tampered with or modified then BOC cannot tell whether or not a regulator complies with AS 4267-1995, even if it is properly marked. If you suspect that your valve has been tampered with or modified, you should not use it. BOC recommends that you use one of the following regulators: Product Code Product Outlet Recommended regulator 060E2 Argoshield Light (E size) side BOC 6000 Argon Regulator 061D2 Industrial Argon (D size) 060D2 Argoshield Light (D size) 070G2 Argoshield 52 (G size) 061G2 Industrial Argon (G size) top BOC 6000 Argon Shielding Gas Regulator 020D2 Industrial Oxygen (D size) side BOC 8000 Single Stage Oxygen Regulator 020E2 Industrial Oxygen (E size) 220G2 Ultra High Purity Helium (G size) top Baseline Single Stage Brass C 106/1-50-4S-T10 Baseline Single Stage Brass C 106/1-150-45-T10 Baseline Dual Stage Brass C 106/2-50-4S-T10 Baseline Dual Stage Brass C 106/2-150-4S-T10 How do I identify the new cylinders? Your new cylinder can be identified by the addition of a ‘2’ next to the cylinder size listed on the shoulder label. For example, a G sized cylinder will become a G2 sized cylinder, E will become E2 and so on. The new cylinders may also have a ‘New Product’ neck tag or shoulder sticker. Who can I contact to find out more? For further questions, send us an email or contact our Customer Service Centre at 131 262. For more information If you have any additional questions, please don’t hesitate to contact us. Phone: 131 262 E-mail ]

-

[ BOC Gas: Catalogue Out Now ]

-

[ BOC to collaborate with CSIRO on revolutionary $3.4m hydrogen project News & Media Press Releases Case Studies Media Contact Competitions AU BOC @ Social Media BOC celebrates 20-year partnership anniversary with Redkite Press Releases BOC celebrates 20-year partnership anniversary with Redkite Leading gases and engineering company BOC, a Member of the Linde Group and Redkite, a charity that supports children and young people throughout the entire cancer journey, are today celebrating their long-term partnership which has spanned two decades and raised almost $2 million. Since becoming Redkite’s first corporate sponsor, BOC has helped the organisation grow into a leading provider of essential support services for young people with cancer and their families – from the moment of diagnosis until after treatment finishes. Jenni Seton, Chief Executive Officer at Redkite said BOC and its staff have shown unwavering support and generosity which has helped thousands of families facing cancer. “BOC was Redkite’s very first corporate partner, and over twenty generous years, they have had a huge impact on generations of families facing childhood cancer. “BOC has been a pioneer in staff engagement and fundraising activities through their innovative KiteTime program. As an organisation, their enthusiasm for building community and looking after families who are really doing it tough has been infectious. “It was BOC who helped Redkite set up a presence in Queensland in 2001. Before this, we didn’t have the resources to help Queensland families. They have also supported many of our flagship fundraising activities including our annual corporate quizzes and education programs. “BOC’s unstinting support and generosity has helped Redkite become the organisation we are today, and we can’t thank them enough.” John Evans, BOC South Pacific Managing Director, said BOC is proud to have supported Redkite for the past 20 years through many different volunteering and company fundraising activities. “The success of this partnership has been driven by the passion of the Redkite team who provide critical support to children and families every day – as well as the commitment shown by BOC employees across Australia to support this very important cause. “There have been many highlights, however as the Principal Sponsor of the Redkite Corporate Quiz, it has been incredibly rewarding to be a part of this annual activity that has raised over $10 million. “We are also very grateful to our many BOC employees who have participated in Kitetime, a workplace initiative that encourages them to take annual leave and donate the pay from these hours to Redkite – as well as the many fun runs, competitions and fundraising efforts.” Further enquiries: Further enquiries: Suzanne Gibbs Head of Communications, RSP Email: suzanne.gibbs@boc.com Email ]

-

[ Pharma & Biotechnology BOC Australia - A Linde company Industries Aquaculture Agriculture Chemicals Construction & Infrastructure Electronics Food, Beverage & Leisure Food processing Glass Processing Healthcare Metal Fabrication Metal Production Mining Steel & Metals Oil and Gas Pharma & Biotechnology Plastics & Rubber Power & Energy Retail Refining Space Mobility & Transport Water & Wastewater Treatment Pharmaceutical & Biotechnology Helping to improve quality of life by enabling innovative therapies and medicines The pharmaceutical and life sciences industry is dedicated to improving quality of life by developing innovative therapies and medicines that promise longer, healthier and more active lives. In the interests of patient safety, this industry is heavily regulated. Compliance, validated quality assurance and traceability are therefore key mandates. This sector also faces rising environmental pressures. In addition, a competitive advantage often hinges on speed, which means that pharmaceutical companies are under pressure to bring their innovations to market as quickly as possible. In general, however, price pressures are squeezing the number of new pharmaceutical products that are being brought to market. This is exasperated by the cost strain that generic drugs are exerting on many firms as brand-name drug patents expire. Long-standing pharmaceutical expertise As a supplier of pharmaceutical-grade gases, we have an in-depth understanding of the pressures facing pharmaceutical and biotech companies in such a strict regulatory environment. We have also developed numerous gas innovations that help meet increasingly stringent environmental legislation and accelerate time to market. Our industrial and specialty gases are available in cylinder or bulk form. You may also have the option of pipeline delivery or on-site production for larger volumes. For your peace of mind, our trained experts can also manage your gas installation. Our expertise will bring you quality and environmental benefits in the following areas in particular: • Inerting, purging & blanketing • Reactor cooling • Solvent recovery & VOC abatement. More information Process: Inerting, purging & blanketing Process: Reactor cooling Process: Solvent recovery & VOC abatement ]

-

[ Vesna Olles About Corporate History Senior Leadership Team Supply and Procurement What we do Vesna Olles Director Clean Energy and Strategy Vesna Olles is the Director Clean Energy and Strategy for BOC South Pacific. She is responsible for strategic innovation, planning and business development for BOC South Pacific, which includes identifying and analysing opportunities that contribute to BOC’s strategic direction for LNG, hydrogen and alternative fuels. Vesna has extensive experience in Australian and global blue-chip companies where she worked across major sectors including industrial, building and construction and gas sectors, in senior and general management positions spanning P&L management, marketing and engineering. Since beginning her career with BOC, she has held multiple positions including General Manager, Sales & Marketing Transformation and General Manager, Channels Strategic Marketing. This role saw her implement a cohesive channel interaction program alongside digital to deliver a seamless and effective cross channel customer experience. She is passionate about leading her teams with integrity and authenticity to deliver outcome. Vesna has a degree in Chemical engineering, and a Masters in Commerce, Marketing and Finance from the University of NSW. Contact BOC Head Office 10 Julius Avenue North Ryde NSW 2113 Australia ABN 95 000 029 729 Phone: +61 2 8874 4400 or email us ]

-

[ BOC to build carbon dioxide facility in Victoria News & Media Press Releases Case Studies Media Contact Competitions AU BOC @ Social Media BOC to build carbon dioxide facility in Victoria Press Releases Leading gas and engineering company BOC, a Linde company, today announced it will build a multi-million dollar carbon dioxide processing facility in Longford, Victoria as part of a new long-term CO2 supply agreement with the Gippsland Basin Joint Venture. The new facility will have the capacity to produce more than 60,000 tonnes of beverage-grade liquid CO2 annually, making it the largest merchant CO2 production facility in the South Pacific. It will significantly increase long-term CO2 reliability and supply for many Australian industries. The Gippsland Basin Joint Venture is a 50-50 joint venture between Esso Australia Resources Pty Ltd (Esso) and Woodside Energy Pty Ltd. Under the agreement, the Gippsland Basin Joint Venture will capture and send CO2 from its Longford Gas Conditioning Plant directly to BOC’s new facility. John Evans, Managing Director of BOC South Pacific said the new facility would increase BOC’s capacity to supply the highest standard of carbon dioxide to customers in Australia and New Zealand. “BOC is building new infrastructure to ensure long-term supply security of an essential gas used in many industries including food processing and packaging, beverage, hospitality, desalination, medical, manufacturing and water treatment,” said Mr Evans. “This significant investment is part of our commitment to develop local supply partnerships and expand our production capability to meet the future needs of our customers and support growth across the South Pacific Region. “With the latest technologies and processes in quality control and efficiency, BOC’s new CO2 facility will exceed internationally recognised food and beverage standards.” Esso Australia Chairman Dylan Pugh said the agreement demonstrates how Esso is taking a leading role in decarbonising its operations while still providing products that are essential for everyday life. “Through this partnership with BOC, we will transform what is effectively a waste stream into a product of beneficial use for Australian businesses in the food, beverage, hospitality, manufacturing and medical industries,” said Mr Pugh. “Esso has a long history of providing reliable energy to Australia, whether it’s powering industry, heating our homes, or fuelling our barbecues, and this partnership will also see Gippsland put the fizz in our drinks.” Woodside Energy Executive Vice President Marketing and Trading Mark Abbotsford said the new agreement was a great example of how businesses can work together to improve societal and environmental outcomes. “Beyond providing energy to keep lights on and support industry, this is one of the many ways that Woodside Energy is collaborating to ensure the reliable and sustainable supply of essential products the community needs and enjoys,” said Mr Abbotsford. “This agreement will support key sectors in our economy, new opportunities for regional jobs as well as our own decarbonisation goals.” Wellington Shire Council Mayor, Cr Ian Bye welcomed BOC to the region in its partnership with Esso, which already has a long-standing relationship with the local community. “This partnership will result in real positives for our region, not only in the jobs created during construction, but also in the role our community will play in providing this important product to the beverage industry,” said Cr Bye. Scoping for the project is well underway with construction expected to commence in 2022, subject to regulatory approvals. Around 60 jobs will be created during the construction phase, with the facility expected to be operational in 2024. About BOC: BOC, a Linde company, supplies compressed and bulk gases, chemicals and equipment across the South Pacific region. Linde is a leading global industrial gases and engineering company with 2021 sales of $31 billion (€26 billion). We live our mission of making our world more productive every day by providing high-quality solutions, technologies and services which are making our customers more successful and helping to sustain and protect our planet. The company serves a variety of end markets including chemicals & energy, food & beverage, electronics, healthcare, manufacturing metals and mining. Linde's industrial gases are used in countless applications, from life-saving oxygen for hospitals to high-purity & specialty gases for electronics manufacturing, hydrogen for clean fuels and much more. Linde also delivers state-of-the-art gas processing solutions to support customer expansion, efficiency improvements and emissions reductions. For more information about the company and its products and services, please visit www.linde.com. Further enquiries: Communications Email: communications@boc.com Email ]

-

[ Lithography Gases BOC Australia - A Linde company Products Equipment & Accessories Gas Products Cylinder Upgrades Supply Modes Lithography Gases Delivering the lithography gas technology used in most of today's semiconductor products For over twenty years, the excimer laser industry has relied on our lithography gases. They were used in the development of the earliest lasers for lithography and are now the most widely used excimer gases for DUV photolithography in the semiconductor industry. Lasers in thousands of the world's wafer steppers and scanners use our state-of-the-art lithography gases and gas mixtures. Our customers include all of the major global laser, stepper, and scanner manufacturers as well as many of the world's largest semiconductor manufacturers. They know they can rely on the highest quality laser gases coupled with in-depth knowledge of critical gas technologies. Our customers also benefit from the development of new technologies and innovations driven by our Centers of Excellence such as the one for lithography gases in Alpha, New Jersey. Key areas of expertise include: Full spectrum - We lead the market for the manufacture and purification of all raw materials necessary for photolithography. Cylinder expertise - We have special expertise, which is based on our proprietary technologies for the handling and treatment of cylinders containing both inert and halogen (F2) gases. Mixing capabilities - We have pioneered highly specific mixing technologies to create multi-component mixtures that are completely homogeneous. Analytical technologies - We have developed proprietary analytical technologies that surpass industry norms; all SPECTRA lithography cylinders are provided with a Certificate of Analysis. Rare gas and halogen gas mixtures for excimer lasers Linde fully supports the gas mixtures required for the entire spectrum of excimer lasers used in electronics manufacturing. XeCl at 308 nm KrF at 248 nm ArF at 193 nm Extreme ultra-violet (EUV) lithography is the next-generation technology that allows the leading-edge semiconductor designs to continue advancing. Large amounts of hydrogen are required to continuously clean the commercial light sources, which use liquid tin as a lasing medium. Linde provides a full portfolio of bulk and on-site H2 solutions for its customers growing requirements. Electronics Office Contact Contact your local Linde sales office Contact us Collateral EUV Lithography Adds to Increasing Hydrogen Demand at Leading-Edge Fabs -Solid State Technology article(PDF 2.0 MB) Excimer Laser Gases: An Exciting Application for Lithography - Gasworld article(PDF 2.0 MB) EUV Lithography Adds to Increasing Hydrogen Demand at Leading-Edge Fabs -Solid State Technology article(PDF 2.0 MB) Market segments Semiconductor Display Solar LED ElectronicsIQ Quarterly Newsletter from Linde Electronics Sign up and read ]

-

[ Sales & Customer Service Sales Professionals and Customer Service Move our business in the right direction. Can you read people? Understand their needs? Do you get the thrill of the sale? Working on the interface between BOC and its customers is a challenging place to be. From laying the foundations of successful relationships to tailoring a solution to their needs all the way to the after-sales; it’s your job to keep BOC out in front. We never rest on our laurels: our business develops and adapts. We only gain market share by being best in class – by having the right experts on our side. Our experts insist on the very best customer experience, the best sales processes and the most effective tools. They seize opportunities and ensure that Linde moves with the times. It’s competitive fast-paced and it’s challenging. Keeping the customer satisfied Can you sense people’s needs before they even ask? We believe that to be “close to the customer”, we should truly understand our customers’ needs in order to develop services that match them. To this end, we continue to roll out initiatives such as the Customer Experience (CX) survey and the Voice of the Customer platform – where customer touchpoints are increased enabling a fast response to their wishes. The right fit for you? We want people who are driven by managing characters, emotions, challenges; people who bring initiative and make their ideas heard. People who embrace change and who are driven to perform at their best by the expectations of others. Our experts in these roles work cross-functionally and internationally. They mentor, manage budgets and key accounts. So if you have all these things as well as the relevant Sales, Marketing, Business Administration or other related background, then this is your fit at BOC. What you could be doing… Gas & Gear Representative (Retail Store) Customer Service Representatives Customer Service Manager Customer Pricing and Asset Officers Customer Query Specialists Account and Territory Managers Sales Manager Business and Market managers Application Sales Engineer Sales Engineer Find a job at your favourite location Search for the right job ]

-

[ BOC Gas: BOC Flexigas G Plan 24 - Argon Industrial Gas Plan $269. No Ongoing Rent. No Cylinder Deposit. Home Plans Industrial Argon G Plan Content for FullForEmpty Attribute Content for No New Business Attribute Previous Next Previous Next Industrial Argon G Plan 24 The Industrial Argon G Plan is ideal for medium gas usage of 1-2 refills per 2 years of G Size (10.2m3) Industrial Argon cylinders. One payment includes 1 full bottle per 2 years. Rent free, no deposit and no need to BYO bottle or cylinder. More information $269.00 per 2 years incl. GST / Price includes 1 full bottle Available: Pick Up | Delivery Sign Up To Plan Plan Details Plan Details Medium Usage Ideal for 1-2 refills per 2 years One payment includes 1 full bottle per 2 years No Ongoing Rent No Cylinder Purchase No Deposit The pricing outlined in this offer is subject to BOC General Terms and Conditions of Supply. The prices exclude any Delivery/Handling charges which may be applicable at the time of purchase. Pre-paid plan offer is not transferable or redeemable for cash or credit. Additional Product Charges will be varied in proportion to changes in BOC's standard prices for each individual product unless otherwise stated in this agreement. This is a rolling plan, unless the cylinder(s) have been returned at renewal date or you advise BOC otherwise. Any cylinders supplied over the agreed plan quantity will be charged at non-plan pricing and rental will apply. All prices include GST. Related Plans Argon Plans View Plans Argoshield Light Plans View Plans Argoshield Univ. Plans View Plans < ]

-

[ Community There are no higher priorities for BOC as an organisation than the health and safety of our employees, customers, suppliers and supporting communities where we work and live. BOC are proud and passionate supporters of Redkite, a national cancer charity that provides assistance to children, young people and their families through the cancer journey and Road Safety Education (RSE) program, a community-based, specialist education initiative providing driver safety education to secondary school students. Please see below for more information about these organisations. Redkite is a national charity that supports children, young people and their family through the cancer journey. Redkite is there from the moment of diagnosis, throughout the rigorous treatment regimes and beyond by providing vital emotional support, financial relief and educational services. Redkite provides essential and practical support for the whole family from the moment of diagnosis, throughout treatment and on return home. BOC staff and families are committed to doing what they can to help the inspirational Redkite team. Volunteering at Redkite events and fundraising activities are just a few ways we lend a hand. BOC became the first major corporate partner of Redkite in 1998, when it was a small yet growing charity then known as The Malcolm Sargeant Cancer Fund for Children. BOC is the major cash sponsor of the Corporate Quiz nights throughout Australia. Employees both attend and volunteer to help at the quizzes. Our relationship with Redkite is even more special due to the dedication and commitment of BOC staff and their families. BOC supports Redkite throughout the year with various fundraising activities, including donating proceeds raised from the City to Surf and Kitetime which is an opportunity for staff to take annual leave and their pay for these leave hours is donated to Redkite. Visit the Redkite website or call 1800 334 771 → Road Safety Education Limited (RSE) is a not-for-profit organisation that delivers highly effective, evidence-based road safety education programs which adhere to recognised “best practice” guidelines to reduce the incidence of youth road trauma in our communities. BOC became the founding sponsor of RSE and the RYDA Program when it was a small yet growing community initiative. Through the sponsorship money BOC have contributed, RSE have been able to expand the program from being a local NSW initiative to venues across Australia and New Zealand. We are most proud to be the Founding Sponsor of RSE and the RYDA Program. RYDA, the flagship program, involves six interactive sessions presented by road safety professionals. At the RYDA Program, attendees hear first-hand from the experts: Driving Instructors Polce Crash Survivors Drug & Alcohol Counsellors Financial Advisors The program has great synergies with BOC’s own safe driving culture – a key reason why the company is so passionate in supporting the development of this important youth education initiative for younger drivers. As part of BOC’s genuine commitment, we also provide our employees with internal safety schemes, such as the benchmarked BOC Driver Safety programme, which promotes safe driving behaviour 100% of the time. RSE youth driver awareness courses. Run for schools in your local area. Visit the website for more info. → ]

-

[ Corporate responsibility Corporate responsibility Framework Health, Safety & Environment (HSE) Health Safety Environment Ethics and Compliance Community Corporate Responsibility Corporate responsibility in the sense of ecological and social sustainability is a top priority for BOC. We feel a strong sense of responsibility towards all of our stakeholders: business partners, employees, our society at large and the environment. This commitment extends across every one of our business areas and locations. At Linde, we live our mission of making our world a better place. Through our high-quality solutions, technologies and services we are making our customers more successful and helping to sustain and protect our planet. Click here to read more. ]

-

[ BOC Gas: G Plan 24 - Argoshield Light Welding Gas Plan $269. No Ongoing Rent. No Cylinder Deposit. Home Plans Argoshield Light G Plan Content for FullForEmpty Attribute Content for No New Business Attribute Previous Next Previous Next Argoshield Light G Plan 24 The Argoshield Light G Plan is ideal for medium gas usage of 1-2 refills per 2 years of G Size (8.7m3) Argoshield Light cylinders. One payment includes 1 full bottle per 2 years. Rent free, no deposit and no need to BYO bottle or cylinder. More information $269.00 per 2 years incl. GST / Price includes 1 full bottle Available: Pick Up | Delivery Sign Up To Plan Plan Details Plan Details Medium Usage Ideal for 1-2 refills per 2 years One payment includes 1 full bottle per 2 years No Ongoing Rent No Cylinder Purchase No Deposit The pricing outlined in this offer is subject to BOC General Terms and Conditions of Supply. The prices exclude any Delivery/Handling charges which may be applicable at the time of purchase. Pre-paid plan offer is not transferable or redeemable for cash or credit. Additional Product Charges will be varied in proportion to changes in BOC's standard prices for each individual product unless otherwise stated in this agreement. This is a rolling plan, unless the cylinder(s) have been returned at renewal date or you advise BOC otherwise. Any cylinders supplied over the agreed plan quantity will be charged at non-plan pricing and rental will apply. All prices include GST. Related Plans Argoshield Light D Plan $108 per year (2.1m3 of gas) incl. GST View details Argoshield Light E Plan $199 per year (4.2m3 of gas) incl. GST View details Argoshield Univ. G Plan $219 per year (8.7m3 of gas) incl. GST View details < ]

-

[ Competitions AU About Corporate History Senior Leadership Team Supply and Procurement What we do Corporate responsibility Framework Health, Safety & Environment (HSE) Ethics and Compliance Community News & Media Press Releases Media Contact BOC @ Social Media Case Studies Competitions AU Contact Your Career at BOC Work @BOC Roles @BOC Jobs @BOC Apply @BOC Incident Response Competition Terms & Conditions There are currently no competitions running. Keep an eye out on our Facebook page for updates on new competitions. ]

-

[ Mine inertisation BOC Australia - A Linde company Industries Aquaculture Agriculture Chemicals Construction & Infrastructure Electronics Food, Beverage & Leisure Food processing Glass Processing Healthcare Metal Fabrication Metal Production Mining Mine inertisation Mineral Flotation Mineral Roasting/Smelting Leaching for gold mining Steel & Metals Oil and Gas Pharma & Biotechnology Plastics & Rubber Power & Energy Retail Refining Space Mobility & Transport Water & Wastewater Treatment Mine Inertisation Use of nitrogen for coal mine inertisation is a key safety feature for coal mines. The combination of heat, fuel (coal) and oxygen are all that are required to start a thermal event. This is often referred to as the fire triangle. Once started these thermal events can run indefinitely causing a significant hazard to workers in the area and causing mines huge financial losses, due to loss of product and mine outages. The use of nitrogen serves to remove the oxygen element in the fire triangle. The nitrogen will help stop an existing fire or prevent one starting. BOC has the ability to supply nitrogen in a wide range of flowrates and via alternate generation methods to mines across Australia and New Zealand, for the purposes of mine inertisation. BOC's demonstrated supply capability and the ability to put storage and vapourisation assets on the ground quickly is un-paralleled throughout the region. BOC has the region's biggest nitrogen production facilities combined with the most extensive network of distribution assets, ensuring we can respond quickly and effectively to any mine thermal event regardless of size. BOC's experience and available assets are a key reason that we have been the trusted partner for decades with NSW Mines Rescue. BOC has the ability to supply, install, operate and maintain equipment that can generate nitrogen on the customer's site. This technology is ideal for customers who need a steady, continuous demand of nitrogen for extended periods. The technology is usually in the form of either a pressure swing absorption system or a membrane system. These systems can be located in one place or made portable to meet the requirements of the customer. Want to find out more? If you would like to find out more about BOC's mining solutions, please complete our contact form and we will be in touch. Contact us ]

-

[ Jobs @ Linde BOC Australia - A Linde company Find your future Search available jobs and career contacts in your region via the drop down below. If you would like to work abroad, Linde, being a truly global company, offers such opportunities. Here, you can get to know more about some of our principal locations. Please select your region Asia Pacific Europe, Middle East & Africa North America South America Please select your region Asia Pacific Europe, Middle East & Africa North America South America The following jobs are available Jobs Australia Career Contact Australia Email The following jobs are available Jobs China Gases Career Contact China Gases Email Career Contact China Engineering Email The following jobs are available Jobs in Linde Engineering India Career Contact India Gases Phone +91.33.6602-1600 Email Career Contact India Engineering Phone +91.265.3056789 Email The following jobs are available Jobs Linde Indonesia Career Contact Indonesia Email The following jobs are available Jobs Linde Korea Career Contact Korea Email The following jobs are available Jobs Linde Malaysia Career Contact Malaysia Email The following jobs are available Jobs New Zealand Career Contact New Zealand Email The following jobs are available Jobs Papua New Guinea Career Contact Papua New Guinea Email The following jobs are available Jobs Linde Philippines Career Contact Philippines Gases Email Career Contact Philippines Linde Global Services Email The following jobs are available Jobs Linde Singapore Career Contact Singapore Email The following jobs are available Jobs Solomon Islands Career Contact Solomon Islands Email The following jobs are available Jobs Linde Thailand Career Contact Thailand Email The following jobs are available Jobs Linde Vietnam Career Contact Vietnam Email The following jobs are available Job Market EMEA Jobs Cryostar France The following jobs are available Jobs Canada Career Contact Canada Career contact can be found in the respective job ad. The following jobs are available Jobs USA – Linde Gas US, Linde Gas & Equipment, Linde Advanced Material Technologies Jobs USA - Corporate Functions, Engineering, Linde Technology (R&D), Center of Excellence, SHEQ, Sustainability, Linde Advance Material Technologies Learn more about Linde in the US Linde Engineering Linde Gas & Equipment Linde Gas US Linde Advanced Material Technologies The following jobs are available Jobs Brazil Gases (White Martins) Career Contact Brazil Telephone: 0800 709 9000 Linde Locations Explore our global hotspots - from New Jersey to Singapore. Meet us Explore our event calendar and click on the teaser for our next careers event. Taking the first step of your career? Explore your options for joining Linde as a student or graduate. Insider tips: From a recruiter Listen up as one of our HR partners gives advice for applying @ Linde. ]

-

[ BOC Gas: BONUS LPG Forklift Gas ]

-

[ BOC Gas: How to Place an Order How to Place an Order Order online for delivery of items The easiest way to order with BOC is to re-order online Register or Sign in to My Account In My Account click Recently Ordered or Re-order Gas & Cylinder Holdings Enter the quantity next to the product you want to re-order Click the Add to Cart & Checkout button Useful Information At checkout you will see all relevant information relating to your order including expected delivery date, delivery charges and cylinder rental fees. Once your gas order has been scheduled for delivery, you will receive an email notifying you of the expected time of arrival. If you purchase equipment you can expect an email once the items are shipped. You can also search and browse our online catalogue to order online When re-ordering using My Account, the shipping and payment options from your most recent online order will be applied to your current order to make it faster for you to order. Read more about Delivery , alternatively find out more information using live chat or call 131 262 to speak with our friendly Customer Service team. Order online for pick-up instore Order online and collect your items from the local Gas & Gear store. Register or Sign in to My Account In My Account click Recently Ordered or Re-order Gas & Cylinder Holdings Enter the quantity next to teh product you want to re-order Click theAdd to Cart & Checkout button During checkout select theFree pick up in-store option Find a local store or use a previously selected store Collecting same day in-store: Orders placed before midday on weekdays and 10am on Saturday (for stores open on Saturday) can request a same day pickup. If you’d like to follow up with the store please contact the store direct. Collecting in-store: Most stores have an allocated space/counter for online pick up customers. Simply present your order details upon arrival. Order details can be printed once you have successfully placed the order online or simply show the order confirmation email in-store. Confirming stock availability: Stock availability can be viewed online when selecting products. Additionally, your nominated store will contact you once your order is ready for pick-up. If a store doesn’t supply a particular product you will be notified at checkout that you are unable to place an order for that item. Collection times: Pick up orders will be reserved for 7 days from order placement. If you are unable to collect before this time please contact the relevant store direct. Visit my local BOC store BOC Gas & Gear stores and our extensive network of Gas Agent & Equipment Partners are always willing to assist. Whether it’s placing an order or answering gas and related product enquiries, our friendly and experienced team are committed to getting the right information you need fast. Locate your nearest store and see opening hours. Call to place an order The BOC Customer Service team understand your time is important, so answering your call promptly is a priority. All calls are answered by experienced team members in Sydney so if you are looking to place an order, enquire about a product or discuss delivery please call us on 131 262 or use live chat to speak with our friendly Customer Service team. Amend or cancel an order If you want to amend or cancel an order you will need to contact the BOC Customer Service Centre. Before contacting us, please ensure you have the order number you wish to amend or cancel. You can then contact us using live chat or call 131 262 where your changes will be made immediately. Chat Online Call Us Send Enquiry Update My Account Looking for a Document Where's My Order? Pricing & Charges Explained Returns & Refunds Chat Online Call Us Send Enquiry Update My Account Looking for a Document Where's My Order? Pricing & Charges Explained Returns & Refunds ]

-

[ BOC Gas: Chat Team Not Available We are unable to chat at this time so please fill in the details below and we will contact you shortly. ]

-

[ F3VIPR Cylinder BOC Australia - A Linde company Supply and Service Supply Options Supply Channels Services Application Technology Centres ACCURA gas cylinder management Cylinder Upgrades Frequently Asked Questions EVOS VIPR F3VIPR Cylinder G3VIPR Cylinder Safety Training The new F3VIPRs will be available across Australia in the following gas codes: Gas Code Gas 061F3VIPR Argon Welding 062F3VIPR Argon High Purity 060F3VIPR Argoshield Light 064F3VIPR Argoshield Super Heavy 065F3VIPR Argoshield Universal 066F3VIPR Argoshield Metal Cored 068F3VIPR Argoshield 40 070F3VIPR Argoshield 52 071F3VIPR Argoshield 54 095F3VIPR Argoshield 100 121F3VIPR Argoshield 12S2 122F3VIPR Argoshield Heavy 069F3VIPR Alushield Heavy 079F3VIPR Alushield Light 127F3VIPR Alushield He10 133F3VIPR Alushield Universal 075F3VIPR Stainshield 092F3VIPR Stainshield Heavy 094F3VIPR Stainshield 69 119F3VIPR Stainshield Light Tips for using the F3VIPR Cylinder: For more information about the F3VIPR, download the below flyer F3 VIPR flyer(PDF 2.0 MB) ]

-

[ BOC Gas: BOC Flexigas G Plan 36 - Carbon Dioxide CO2 Industrial Gas Plan $269. No Ongoing Rent. No Cylinder Deposit. Home Plans Industrial Carbon Dioxide G Plan Content for FullForEmpty Attribute Content for No New Business Attribute Previous Next Previous Next Industrial Carbon Dioxide G Plan 36 The Industrial Carbon Dioxide G Plan 36 is ideal for medium gas usage of 1-2 refills per 3 years of G Size (31kg) Industrial Carbon Dioxide cylinders. One payment includes 1 full bottle per 3 years. Rent free, no deposit and no need to BYO bottle or cylinder. More information $269.00 per 3 years incl. GST / Price includes 1 full bottle Available: Pick Up | Delivery Sign Up To Plan Plan Details Plan Details Medium Usage Ideal for 1-2 refills per 3 years One payment includes 1 full bottle per 3 years No Ongoing Rent No Cylinder Purchase No Deposit The pricing outlined in this offer is subject to BOC General Terms and Conditions of Supply. The prices exclude any Delivery/Handling charges which may be applicable at the time of purchase. Pre-paid plan offer is not transferable or redeemable for cash or credit. Additional Product Charges will be varied in proportion to changes in BOC's standard prices for each individual product unless otherwise stated in this agreement. This is a rolling plan, unless the cylinder(s) have been returned at renewal date or you advise BOC otherwise. Any cylinders supplied over the agreed plan quantity will be charged at non-plan pricing and rental will apply. All prices include GST. Related Plans Carbon Dioxide D Plan $79 per year (6kg of gas) incl. GST View details Carbon Dioxide E Plan $149 per year (15kg of gas) incl. GST View details Oxygen G Plan $199 per year (8.9m3 of gas) incl. GST View details < ]

-

[ BOC to launch new SOLVOX technology at World Aquaculture Conference News & Media Press Releases Case Studies Media Contact Competitions AU BOC @ Social Media BOC to launch new SOLVOX technology at World Aquaculture Conference 28 May 2014 Press Releases Leading gases and engineering company BOC will showcase its newest SOLVOX oxygenation technology to Australian fish farmers for the first time at the World Aquaculture Adelaide Conference & Trade Show in June. In global collaboration with BOC’s parent company the Linde Group, BOC is helping major seafood companies in Tasmania, New Zealand and elsewhere optimise production volume and meat quality whilst reducing their environmental footprint though cutting edge aquaculture application technologies. The new SOLVOX solution being unveiled in in Adelaide from June 7‐11, is the latest development in low and medium pressure oxygenation systems to take Australian fish farming to the next level. The flexible SOLVOX oxygen dissolving equipment can be applied to any fish tank to establish optimum environmental conditions, thus improving fish health and allowing for faster growth. BOC is a leading end‐to‐end supplier to fish farms, offering industrial gas supply, specialist oxygenation and control equipment, installation and consultant services, as well as training and optimisation of the system, supported by an international network of experts to develop tailored solutions. The exciting new technology now available to Australian and New Zealand aquaculture operators was developed at Linde’s Innovation Centre of Aquaculture which opened in Norway in 2012. Located in Ålesund in the heart of the world’s most industrialised fish farming community, the centre features a range of highly equipped laboratories and number of test and demonstration aquaculture tanks. Leading aquaculture expert Kenneth Glomset, Market Development / Project Manager Aquaculture & Water Treatment from the Innovation Centre will attend the Adelaide conference to demonstrate the SOLVOX technology. Jon Hawton, BOC’s Market Manager – Food and Beverage said the new oxygen dissolution technologies were “streets ahead” of anything else currently available. “We are excited about the new SOLVOX technology range and are very pleased to be introducing it into Australia. The technology can be integrated into new or existing water distribution systems and tailored to suit most customer requirements,’’ he said. “Easy to install, the unit can be retrofitted into the pipework of existing fish tanks to oxygenate the entire flow entering the tank.” Maintaining proper oxygen levels ‐ in fresh water or salt water ‐ is important to enable the fish to combat disease and leads to stable production and economic benefits for the farmer. The correct dissolved oxygen level for optimal fish growth depends on species, size, feeding rate, activity level and water temperature. In closed or recycled systems, increased oxygen saturation levels are essential for fish survival. The dissolution of oxygen and transfer rate is greatly improved when using pure oxygen as opposed to air; this significantly reduces pressure requirements and pumping power and avoids the risk of super saturation. SOLVOX offers a unique low‐pressure oxygenation system which significantly increases fish production volume, optimises fish meat quality and considerably improves fish farming operations from an environmental standpoint. SOLVOX is a combined oxygenation and flow system which not only dissolves the optimal amount of oxygen in the inlet water flow, but also distributes it evenly at an adjustable flow pattern through the tank, ensuring fish stock physically benefit from exercise against the flow. The flow regime can be fully tailored according to fish size, stock density and fish species, such as salmon or cod. Due to its high efficiency, very low energy requirements and the positive effects of creating and maintaining an optimal environment for fish, SOLVOX can significantly contribute to cost efficiencies in on‐land fish production. In addition, the ability to produce fish from infancy to maturity in on‐land tanks has significant environmental benefits. The water flowing through fish tanks can be recycled to a high extent with excrements and feed residues filtered out effectively. As such, pollution to the marine environment and the possible spread of disease to wild fish is prevented. The key benefits of the SOLVOX range are: Reduced fish mortality Improved feed conversion rate Improved growth rate Increased stocking densities Healthier, hence higher quality fish The SOLVOX systems will be on display at the BOC stand at the World Aquaculture Adelaide Conference www.aquaculture.org.au at the Adelaide Convention Centre from June 7‐11 2014. Further enquiries: Further enquiries: Suzanne Gibbs Head of Communications, RSP Email: suzanne.gibbs@boc.com Email ]

-

[ BOC Gas: BOC Flexigas D Plan 12 - Nitrogen Industrial Gas Plan $79. No Ongoing Rent. No Cylinder Deposit. Home Plans Industrial Nitrogen D Plan Content for FullForEmpty Attribute Content for No New Business Attribute Previous Next Previous Next Industrial Nitrogen D Plan 12 The Industrial Nitrogen D Plan is ideal for low gas usage of 1-2 refills per year of D Size (1.4m3) Industrial Nitrogen cylinders. One annual payment includes 1 full bottle. No ongoing rent, no deposit and no need to BYO bottle or cylinder. More information $79.00 per year incl. GST / Price includes 1 full bottle Available: Pick Up | Delivery Sign Up To Plan Plan Details Plan Details Low Usage Ideal for 1-2 refills per year One annual payment includes 1 full bottle No Ongoing Rent No Cylinder Purchase No Deposit The pricing outlined in this offer is subject to BOC General Terms and Conditions of Supply. The prices exclude any Delivery/Handling charges which may be applicable at the time of purchase. Pre-paid plan offer is not transferable or redeemable for cash or credit. Additional Product Charges will be varied in proportion to changes in BOC's standard prices for each individual product unless otherwise stated in this agreement. This is a rolling plan charged annually unless the cylinder(s) have been returned at renewal date or you advise BOC otherwise. Any cylinders supplied over the agreed plan quantity will be charged at non-plan pricing and rental will apply. All prices include GST. Related Plans Nitrogen E Plan $139 per year (3.6m3 of gas) incl. GST View details Nitrogen G Plan $199 per year (7.2m3 of gas) incl. GST View details Oxygen D Plan $79 per year (2m3 of gas) incl. GST View details < ]

-